20MNCR5 STEEL

20MNCR5 STEEL GRADE

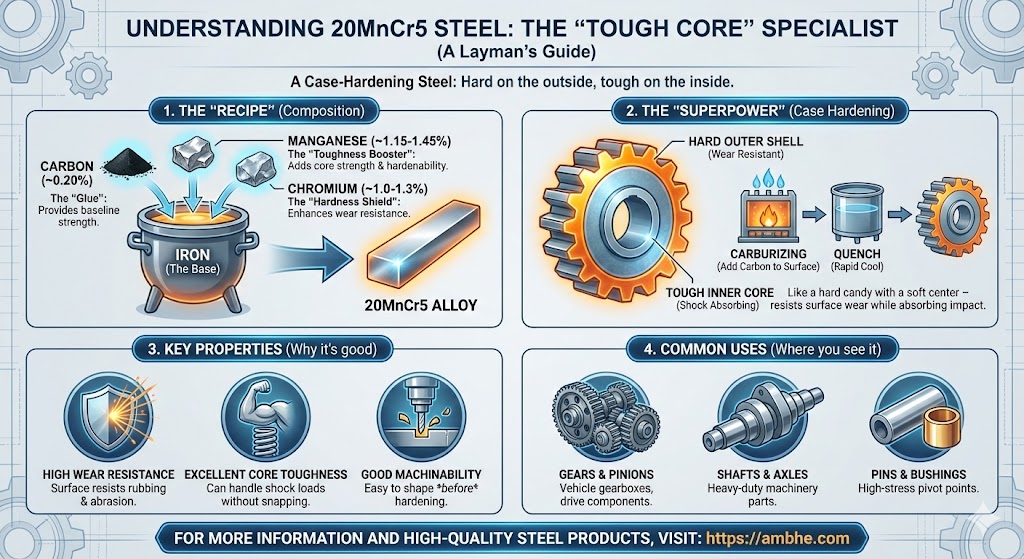

20MnCr5 steel is a low alloyed engineering case hardening steel for parts which require core tensile strength of 1000 – 1300 N/mm² and good wearing resistance.

It is used in boxes, piston bolts, spindles, camshafts, gears, shafts and other mechanical controlling parts.

We are manufacturers of 20MnCr5 steels in India and regularly make sizes from 23.5mm to 80mm in round form. We also manufacture 20MnCr5 in cold drawn bright bar form from 22mm to 63.5mm. Also, we make 20MnCrS5 steel in round-cornered square (RCS) form of sizes 55mm, 63mm and 75mm. You can ask for a quotation to compare with your existing supplier prices.

We can also provide you with 16MnCr5 alloy steels and 16MnCr5/20MnCr5 dual certified steels.

One of the unique properties of 20MnCr5 steel is its ability to be case-hardened. This process involves heating the steel to a high temperature, then rapidly cooling it. This causes the surface of the steel to harden, while the interior remains relatively soft.

The case-hardening process also allows for greater control over the hardness of the steel, as different amounts of elements can be added to achieve different levels of hardness. This means that 20MnCr5 steel can be used in a wide range of applications, from gears and shafts to other mechanical components that need to be strong and durable.

This steel is carburising steel used for components requiring high wear resistance surface, coupled with tough cores to resist shock loads and strength to give large service life.

Overall, 20MnCr5 steel is a versatile and durable steel that is commonly used in the production of gears, shafts, and other mechanical components. This steel can be cut, drilled, and machined with relative ease, making it a popular choice for many different applications. Its ability to be case-hardened and its ease of machining make it a popular choice for many different applications. Additionally, its ability to be welded makes it a popular choice for many different types of structures and machines.

The Indian equivalent of this standard can be found in IS9175 (Part 20).

Ordering Information

To order, the following information will be required

| Grade | 20MnCr5 |

| Order | Minimum order 3MT per size |

| Length | a) 5 To 6 Meters b) Custom Cut Length or multiple |

| Round Diameter | 23.5 mm to 80 mm |

| Condition | a) Hot Rolled b) Bright Bar |

To request a quote kindly fill up this form.

Contact us for 20MnCr5 Steel

Would you like to know the pricing for 20MnCr5 bars? Contact us

Via email: sales@ambhe.com

Via Telephone: +91 9820225662

For more detailed contact information visit https://ambhe.com/contact/

Testing and Packaging

Testing and packaging are considered one of the most critical steps of the manufacturing process.

We do several tests and inspections to check the quality of 20MnCr5 steel round bar. Tests done depend on the requirement of the users. Those quality tests can include chemical composition test, physical test, visual inspection, macro and micro test, NDT tests such as MPI and ultrasonic test depending on the requirement of the customers. We can also arrange a third-party inspection if required. A test certificate is given for each consignment for the tests conducted.

At last, we bundle or pack the 20MnCr5 round bar to prevent damage at the time of transportation.

About our Company

Ambhe Ferro Metal Processors Private Limited is a well-known and reputed manufacturer of IS2062 steel round bar situated in the state of Maharashtra, India. The location of our factories is near the port of JNPT and the major consumption centres of Mumbai, Thane, Pune, Nasik, Ahmednagar and Aurangabad.

Ambhe is manufacturing a wide range of round bars and other products as per the demand of customers. We make these bars in varied shapes and sizes so that we can fulfil all the needs and desires of customers. We manufacture our products keeping in mind the quality parameters and requirement set by the industry. These round bars are known best for their excellent features and quality. We manufacture high-quality bars as per domestic as well as global specifications as per the requirement of the customer.

We make use of top-notch quality of raw material and systems as per the needs of the customer. Kindly explore this website to know more about us.

Percentage of Elements in Chemical Composition of grade 20MnCr5 steel (1.7147): EN 10084-2008

Elements not quoted in this table shall not be intentionally added to the steel without the agreement of the purchaser, other than for the purpose of finishing the heat.

| C | Si | Mn |

0.17 – 0.22 | 0.15 – 0.4 | 1.1 – 1.4 |

| P | S | Cr |

max 0.025 | 0.015 – 0.035 | 1 – 1.3 |

Hot Working and Heat Treatment Temperatures

-

Soft Annealing of 20MnCr5 steel

Heat to 650-700 oC. -

Carburizing

Temperature 900-950 oC . Cooing from carburizing temperature: water, oil, air, thermal bath, cooling box. -

Hardening

Core hardening 850 – 880 oC. Case hardening: 810 -840 oC. Quenching media: water, oil, air, thermal bath. -

Tempering

Tempering temperature: 150-200 oC. -

Forging

Hot Forming temperature: 1100-850 oC. -

Rolling

Rolling temperature 1220 oC , Finishing Templerature > 900oC -

Normalising

850-880 oC, air cool

Mechanical Properties of 20MnCr5 Steel

UTS in N/mm2 , refined and quenched, min.:980 (100kg/mm2)

Elongation %, refined and quenched, min: 8

Izod Impact in kgm, min.: 3.8

Equivalent Grades

- AFNOR: 20MC5

- SAE : 5120

- 20MnCrS5, 1.7147

Grades we Manufacture

- Gears: 20MnCr5 steel is commonly used in the production of gears due to its ability to be case-hardened and its excellent wear resistance. This makes it well-suited for gears that are exposed to high levels of wear and tear.

- Shafts: The combination of strength, toughness and wear resistance make 20MnCr5 steel a suitable option for shafts in various industries such as automotive and heavy machinery.

- Axles: 20MnCr5 steel is also commonly used in the production of axles for automobiles, trucks, and other vehicles. Its ability to be case-hardened and its excellent wear resistance make it well-suited for this application.

- Cams and Camshafts: The case-hardening property of 20MnCr5 steel makes it a suitable option for the production of cams and camshafts, which are subject to high levels of wear and tear.

- Crankshafts: The combination of strength and toughness in 20MnCr5 steel makes it a suitable option for crankshafts in internal combustion engines.

- Gearboxes: 20MnCr5 steel is often used in the production of gearboxes due to its strength and durability. Its ability to be case-hardened also makes it well-suited for gears in gearboxes that are exposed to high levels of wear and tear.

- Transmission parts: The strength, toughness and wear resistance of 20MnCr5 steel make it suitable for the production of transmission parts in automobiles, trucks, and other vehicles.

- Machine parts: 20MnCr5 steel is also commonly used in the production of machine parts, such as gears and shafts, due to its ability to be machined and processed easily.

- Heavy-duty machinery: 20MnCr5 steel is often used in the production of heavy-duty machinery, such as construction equipment and industrial machinery, due to its strength and durability.

- Agriculture equipment: The wear resistance property of 20MnCr5 steel makes it suitable for the production of gears and other components in agriculture equipment, such as tractors and threshers.

Why is 20MnCr5 used as raw material for gears?

20MnCr5 has a single alloying element, Chromium. It is a low alloy steel capable of being hardened upto HRC 41. This provides a tough core and can be case hardened by carburizing or carbonitriding to achieve a hard case. This alloy would be useful for items such as Spur gears and helical gears that require little or no size change during heat treatment and no post heat treatment finishing operations.

Markets

We supply 20MnCr5 to various national and international markets.

In India, we supply 20MnCr5 steel to a number of companies/industries in Mumbai (eg Vasai Virar, Mira Bhayendar, Navi Mumbai), Pune (eg. Pimpri Chinchwad, Chakan, Bhosari, Ranjangaon, etc), Aurangabad (eg. Waluj, Chikalthana, etc.), Nashik (eg. Ambad, Satpur, Sinnar, etc.), Ahmednagar, Rajkot, Ahmedabad, Thane, Umergaon, Ambernath, Rabale, Nagpur, Kolhapur, Sangli, Belgaum, Bangalore, Goa, Chennai, UAE, etc.