ANNEALED STEEL BAR

Annealed Steel Bars

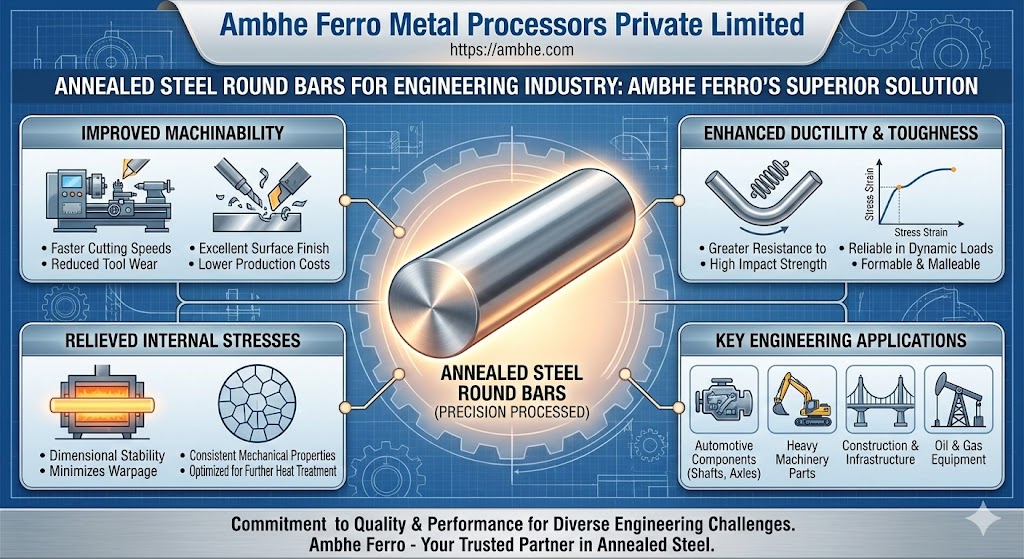

Annealing, in metallurgy and materials science, is a heat treatment that alters the physical properties of a material to increase its ductility and reduce its hardness, making it more workable. It involves heating a material to above its recrystallization temperature, maintaining a suitable temperature, and then cooling. We can provide you Annealed Steel Bars of Grades such as SAE4140, En9, etc.

For inquiries kindly call us today on 9004064570 or email us on sales@ambhe.com

Annealed Alloy Steel Bars — Ambhe Ferro

Why Annealed Bars from Ambhe Ferro?

Consistent machinability: Controlled anneal cycles for uniform hardness across heat and cross-section.

Lower tool wear & cycle time: Softer matrix and stress relief deliver smoother chips and longer insert life.

Better downstream heat treatment: Predictable response in Q&T/carburising thanks to refined microstructure.

Tight dimensional control: Turned/peeled, drawn or ground options with straightness and surface guarantees.

Pan-India logistics: Fast dispatch from Maharashtra to all major industrial hubs.

Technical support: Grade selection, hardness targets, and machining and heat-treatment guidance.

Typical Supply Range (Indicative)

Sizes (rounds): 23.5mm–80 mm (larger/smaller on request)

Lengths: 3–6 m (fixed-length cut pieces available)

Conditions: +A (annealed), +AC (spheroidised/soft annealed), +SR (stress-relieved)

Finishes: Black / Turned & Peeled / Drawn & Polished / Centreless Ground

Straightness: up to 0.5–1.0 mm/m (finish-dependent)

Hardness (typical, post-anneal): 160–235 HBW (grade-dependent; tighter bands on request)