Alloying Elements of Steel

Alloying Elements of Steel

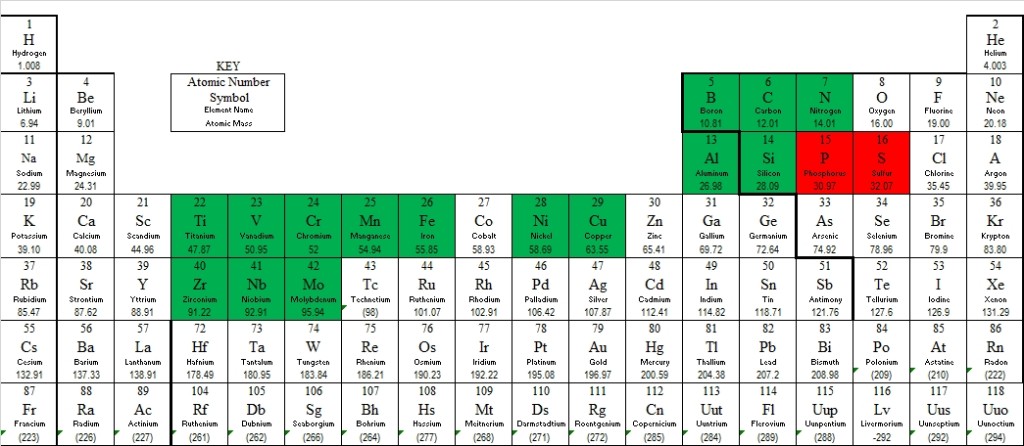

All steels contain a number of alloying elements depending on the properties required. There are certain elements required in the very formation of steel apart from iron (Fe). Following are the elements normally added to steel

ALUMINIUM – Al

Used to deoxidize steel and control grain size with additions up to around 0.05 wt. percent. Grain size control is accomplished by the formation of a fine dispersion of aluminium nitride precipitates, which restricts austenite grain growth. Aluminium can be added at higher levels as an effective nitride former in nitriding steels.

BORON – B

Usually added between 0.0005-0.003 wt. percent to significantly increase the hardenability, especially for low carbon alloys. It does not affect the strength of ferrite, and therefore has little effect on ductility, formability or machinability in the annealed or soft state.

CALCIUM – Ca

Used in certain steels to control the composition, type, shape, size and distribution of oxide and/or sulphide inclusions. Benefits may include improved ductility, impact strength and/or machinability. Ca can also be added to improve castability.

CARBON – C

The most important alloying element which is essential for the formation of cementite, graphite, pearlite, spheriodite, bainite, and iron-carbon martensite. Strength, hardness, hardenability, and ductile-to-brittle transition temperature are increased with increasing carbon content up to approximately 0.60 percent. Toughness and ductility of steels are decreased with increasing carbon content. The maximum achievable hardness level of a martensitic steel is a function of carbon content only, with hardness level increasing with carbon content.

CHROMIUM – Cr

Used in alloy steels to increase 1) resistance to corrosion and oxidation, 2) high temperature strength, 3) hardenability, and 4) abrasion resistance in high carbon alloys. Straight chromium steels are susceptible to temper embrittlement and can be brittle.

COPPER – Cu

Detrimental to hot workability and subsequent surface quality and is normally restricted to residual levels. It is used in certain steels to improve resistance to atmospheric corrosion.

LEAD – Pb

Can be added at the steel melting stage to improve machinability.

MANGANESE – Mn

A common alloying element used in most steels because it deoxidizes the melt, facilitates hot working of the steel by reducing the susceptibility to hot shortness due to sulphur content and adds to hardenability. Mn also partially combines with sulphur to form MnS inclusions, which are commonly used to increase machinability. Mn also improves pearlitic strength in the non-hardened state, and is a major element used in micro-alloyed steels.

MOLYBDENUM – Mo

Increases hardenability of steels and helps maintain a specified hardenability. It increases high temperature tensile and creep strengths. Molybdenum hardened steels require higher tempering temperatures for softening purposes.

NICKEL – Ni

Used in low alloy steels to reduce the sensitivity of the steel to variations in heat treatment and distortion and cracking on quenching. It also improves low temperature toughness and hardenability.

NIOBIUM – Nb (Columbium – Cb)

Lowers transition temperature and raises the strength of low carbon steel. Niobium increases strength at elevated temperatures, results in finer grain size and forms stable carbides, lowering the hardenability of the steel.

NITROGEN – N

Increases the strength, hardness and machinability of steel, but it decreases the ductility and toughness. In aluminium-killed steels, nitrogen combines with the aluminium to provide grain size control, thereby improving both toughness and strength. Nitrogen can reduce the effect of boron on the hardenability of steels.

PHOSPHORUS – P

Generally restricted to below 0.06 weight percent to minimize its detrimental effect on ductility and toughness. Certain steels may contain higher levels to enhance machinability, strength and/or atmospheric corrosion resistance.

SILICON – Si

One of the principal deoxidizers with the amount used dependent on the deoxidization practice. It slightly increases the strength of ferrite without a serious loss of ductility. In larger quantities, it aids the resistance to scaling up to a certain temperature in air and decreases magnetic hysteresis loss.

SULPHUR – S

Detrimental to transverse strength and impact resistance. It affects longitudinal properties to a lesser degree. Existing primarily in the form of manganese sulfide stringers, sulfur is typically added to improve machinability.

TELLURIUM – Te

Added to steel to modify sulphide-type inclusion size, morphology and distribution. The resulting sulphide-type inclusions are finer and remain ellipsoidal in shape following hot working, thereby improving transverse properties.

TITANIUM – Ti

Added to boron steels because it combines with oxygen and nitrogen, thus increasing the effectiveness of boron. Titanium, as titanium nitride, also provides grain size control at elevated temperatures in micro-alloy steels. In excess, titanium is detrimental to machinability and internal cleanliness.

Tungsten – W

Steels also can have varying amounts of tungsten in their composition. Some of this is residual and unintended, such as in 1018 steel. However, some steels have added amounts of tungsten to improve the mechanical and chemical properties of the steel for different applications. Because of its high melting temperature, tungsten can be used to increase the melting temperature of steel. The high hardness of tungsten can also increase the wear resistance of steel. Lastly, tungsten can also improve the corrosion resistance of steel.

Steels also can have varying amounts of tungsten in their composition. Some of this is residual and unintended, such as in 1018 steel. However, some steels have added amounts of tungsten to improve the mechanical and chemical properties of the steel for different applications. Because of its high melting temperature, tungsten can be used to increase the melting temperature of steel. The high hardness of tungsten can also increase the wear resistance of steel. Lastly, tungsten can also improve the corrosion resistance of steel.

The amount of tungsten in an alloy steel can range widely. In high strength low alloy steel, it can be under 1%. High speed tool steels, where tungsten is frequently used as an alloying element, can have amounts of tungsten greater than 15% by weight. Examples of high speed tool steels with tungsten include T1, M1, and M7, to name a few.

VANADIUM – V

Inhibits grain growth during heat-treating while improving strength and toughness of hardened and tempered steels. Additions up to 0.05 percent increase hardenability whereas larger amounts tend to reduce hardenability because of carbide formation. Vanadium is also utilized in ferrite/pearlite micro-alloy steels to increase hardness through carbonitride precipitation strengthening of the matrix.

For Further Studies