16MNCR5 STEEL

16MNCR5 STEEL GRADE

16MnCr5 – Chrome Manganese Case Hardening Steel

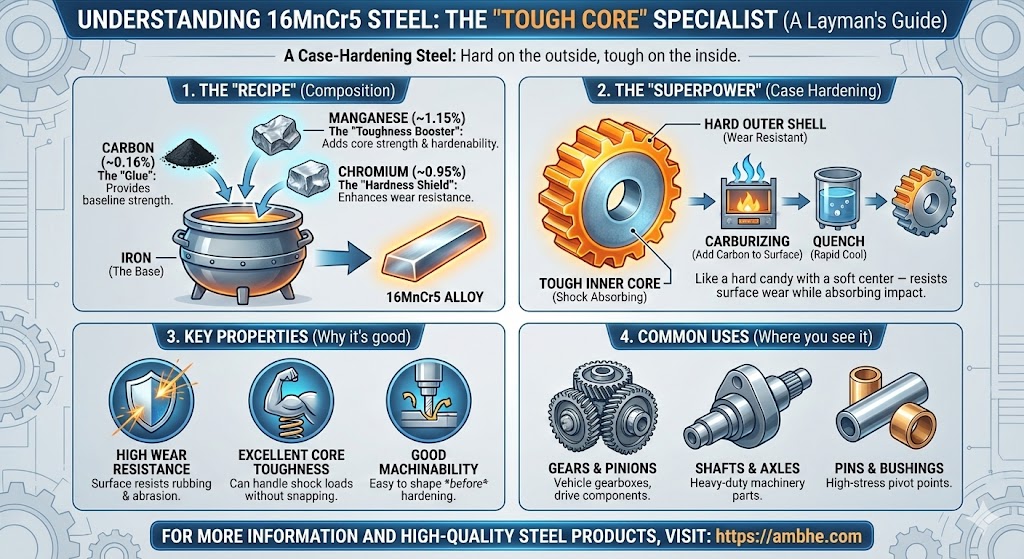

Overview 16MnCr5 is a premium low-alloy Chrome-Manganese steel designed specifically for case hardening applications. It is renowned for delivering a superior surface hardness while maintaining a tough, ductile core.

Key Advantages

Exceptional Machinability: Engineered for efficiency, 16MnCr5 can be cut, drilled, and processed with relative ease, reducing machining time and tool wear.

Superior Wear Resistance: Its high surface hardness makes it the ideal choice for heavy-duty components like gears, shafts, and pinions exposed to constant friction and stress.

Strength & Flexibility: Offers an optimized balance of high tensile strength and ductility, ensuring components can withstand shock loading without brittle failure.

Weldability: The grade is suitable for various structural applications due to its reliable welding characteristics.

Our Manufacturing Capabilities We regularly manufacture and stock high-quality 16MnCr5 in a wide range of sizes:

Round Bars: 23.5mm to 80mm

Bright Bars: 22mm to 63.5mm

RCS (Round Corner Squares): 55mm to 75mm

Follow the link to find our Size Range.

Quality Assurance We guarantee quality through rigorous testing protocols. All material is subject to Ultrasound (UT) and Magnetic Particle Inspection (MPI) to ensure internal soundness and surface integrity.

Trusted Supplier Across Western India We are a preferred supplier to major industrial hubs, including Mumbai, Pune (Chakan, Bhosari, Ranjangaon), Aurangabad, Nashik, Ahmednagar, Rajkot, Thane, and Nagpur.

Related Products We also manufacture 20MnCr5 and offer Dual Certified 16MnCr5/20MnCr5 steel for versatile inventory management.

About our Company

Ambhe Ferro Metal Processors Pvt. Ltd. Your Trusted Partner for 16MnCr5 Steel Bars in Maharashtra

Ambhe Ferro Metal Processors is a premier manufacturer producing high-performance 16MnCrS5 steel. We combine advanced manufacturing systems with premium raw materials to deliver products that meet rigorous global and domestic specifications.

Why Choose Ambhe?

Strategic Advantage: Located near JNPT Port for exports and central to major hubs like Mumbai, Pune, and Aurangabad for fast local delivery.

Custom Solutions: We manufacture a wide range of sizes and shapes, offering bespoke solutions to fulfill even the most complex client preferences and requirements.

Superior Quality: Our bars are known for their exceptional features, including high ductility, structural integrity, and flawless finish.

Rigorous Testing: Every batch undergoes strict quality checks to ensure it meets industry parameters before dispatch.

Explore our website to discover how our steel can strengthen your supply chain.

16MnCr5 Steel Chemical Composition (EN 10084)

The chemical composition of 16MnCr5 is strictly controlled under the EN 10084 standard. It is a low-carbon alloy steel that relies on specific additions of Manganese (Mn) and Chromium (Cr) to achieve its high surface hardness and core toughness.

Standard Composition Table (Weight %)

| Element | Symbol | Minimum % | Maximum % |

|---|---|---|---|

| Carbon | C | 0.14 | 0.19 |

| Manganese | Mn | 1.00 | 1.30 |

| Chromium | Cr | 0.80 | 1.10 |

| Silicon | Si | - | 0.40 |

| Phosphorus | P | - | 0.025 |

| Sulphur | S | 0.020 | 0.035 |

Role of Alloying Elements

Understanding why these elements are present helps in selecting the right heat treatment.

- Function: Carbon is purposely kept low. This ensures the "Core" of the steel remains ductile and shock-absorbing even after heat treatment.

- Comparison: If the carbon were higher (like in 20MnCr5), the core would be stronger but less ductile (more prone to snapping under shock).

- Function: Manganese acts as a primary hardener. It increases the "Hardenability" of the steel, allowing it to be quenched in Oil rather than Water.

- Benefit: Oil quenching is slower and gentler than water quenching, which significantly reduces the risk of the part warping or cracking.

- Function: Chromium is the key to "Case Hardening." It helps the carbon penetrate the surface during the Carburizing process.

- Benefit: It ensures the high hardness extends deep into the part (Hardness Depth), giving gears a long service life.

Supply Specifications & Ordering Information for 16MnCr5 steel

To ensure a seamless enquiry process, please review our standard manufacturing parameters below. When requesting a quote, kindly specify the Grade, Size, and Condition.

| Parameter | Ambhe Ferro Specification |

|---|---|

| Material Grade |

16MnCr5 (DIN 1.7131 / EN 10084) Dual certification with 20MnCr5 available on request. |

| Diameter Range | 23.5 mm to 80 mm (Rounds) |

| Surface Condition |

|

| Length Options |

• Standard: 5.5 to 6.0 Meters • Custom: Fixed lengths or multiples available. |

| Minimum Order (MOQ) | 5 MT (Metric Tonnes) per size |

Ordering Information

Want to Order?

Get competitive pricing and immediate delivery for 16MnCr5 Steel. Contact our Mumbai sales office today.

(Response within 24 Hours)

Grades Equivalent to 16MnCr5 steel

International Equivalents for 16MnCr5 (1.7131)

The table below provides a cross-reference of global standards equivalent to 16MnCr5 (DIN 1.7131).

| Region / Standard | Standard Body | Grade | Notes |

|---|---|---|---|

| Europe (EU) | EN 10084 | 16MnCr5 | The primary modern standard. |

| Germany | DIN / W.Nr. | 1.7131 | The universally recognized "Werkstoff Number". |

| USA | AISI / SAE | 5115 | Nearest equivalent. (See Note 1 below) |

| USA | UNS | G51150 | Unified Numbering System. |

| United Kingdom | BS 970 (Legacy) | 527M17 / 590M17 | Largely superseded by EN 10084. |

| Japan | JIS G4053 | SCr415 | Nearest equivalent. Lower Mn content. (See Note 2) |

| China | GB/T 5216 | 16CrMnH | Direct equivalent. |

| China | GB/T 3077 | 20CrMnTi | Common substitute. Contains Titanium. (See Note 3) |

| Russia | GOST | 18KhG | - |

| France | AFNOR | 16MC5 | Legacy designation. |

- Note 1 (USA - AISI 5115): While 5115 is the standard US reference, it typically has lower Manganese (0.70%–0.90%) than 16MnCr5 (1.00%–1.30%). For high-stress gears, 16MnCr5 offers superior hardenability.

- Note 2 (Japan - SCr415): Similar to the US grade, JIS SCr415 has lower Manganese (0.60%–0.85%). If your drawing specifies SCr415, using 16MnCr5 is often a safe upgrade, but check with your engineering team first.

- Note 3 (China - 20CrMnTi): This is the dominant gear steel in China. It contains Titanium (Ti) for grain refinement. It is a substitute, not a direct chemical equivalent to 16MnCr5.

FAQ on 16MnCr5 Steels

Frequently Asked Questions about 16MnCr5

What is 16MnCr5 Steel (DIN 1.7131)?

What is the Chemical Composition of 16MnCr5?

How does 16MnCr5 compare to EN353?

What is the recommended Heat Treatment for 16MnCr5?

Why is Grain Size important in 16MnCr5?

Can 16MnCr5 be machined easily?

Does Ambhe Ferro provide Mill Test Certificates (MTC)?

What forms of 16MnCr5 are available?

What industries use 16MnCr5?

Heat Treatment Properties & Guidelines for 16MnCr5

Heat Treatment Guide for 16MnCr5 (1.7131)

16MnCr5 is a Case Hardening steel designed to achieve a dual structure: a hard, wear-resistant surface (Case) and a tough, shock-absorbing center (Core). The following data adheres to EN 10084 and DIN 17210 standards.

1. Quick Reference: Temperatures & Process

| Process Step | Temperature (°C) | Cooling Medium |

|---|---|---|

| Forging | 850°C – 1150°C | Air |

| Soft Annealing | 650°C – 700°C | Furnace (Slow Cool) |

| Carburizing | 880°C – 980°C | Endo Gas / Powder |

| Core Hardening | 860°C – 900°C | Oil / Polymer |

| Case Hardening | 780°C – 820°C | Oil / Polymer |

| Tempering | 150°C – 200°C | Air (Min 1 Hour) |

2. Detailed Process Guidelines

A. Soft Annealing (Pre-Machining)

Before machining gears or shafts, the steel must be annealed to maximize tool life. Heat to 650°C – 700°C and cool slowly in the furnace. This produces a hardness of maximum 207 HB.

B. Carburizing & Hardening

Carbon is introduced to the surface at 880°C – 980°C. Following this, the component is Quenched (hardened).

Target Hardness:

- Surface Hardness: 58 – 62 HRC (Rockwell C)

- Core Hardness: 30 – 45 HRC (Dependent on section size)

C. Tempering (Stress Relief)

Crucial Step: Tempering must be performed immediately after quenching (while the part is still warm) at 150°C – 200°C for at least 1-2 hours. This prevents grinding cracks and improves toughness without significantly lowering the surface hardness.

3. Mechanical Properties (Core Strength)

The strength of the "Core" depends on the diameter (ruling section) of the part. Thicker parts cool slower and retain more ductility but less hardness.

| Diameter (mm) | Tensile Strength (Rm) | Yield Strength (Re) | Elongation (%) | Impact Energy (KV) |

|---|---|---|---|---|

| < 11 mm | 1000 – 1300 MPa | ~ 700 MPa | 8% | - |

| 11 – 30 mm | 800 – 1100 MPa | ~ 600 MPa | 10% | 30 J |

| 30 – 63 mm | 650 – 950 MPa | ~ 450 MPa | 11% | 35 J |

4. Jominy Hardenability (+H Grades)

16MnCr5 is often specified with a restricted hardenability band to ensure consistent distortion during heat treatment. This is verified using the Jominy End Quench Test.

- 16MnCr5: Standard range.

- 16MnCr5+H: Tested hardenability.

- 16MnCr5+HH: High hardenability (Upper curve).

- 16MnCr5+HL: Low hardenability (Lower curve).

Quality Assurance, Testing & Packaging for 16MnCr5

At Ambhe Ferro, we consider testing and packaging to be as critical as the melting process itself. Our quality control protocols ensure that every 16MnCr5 round bar leaving our factory is defect-free and ready for immediate machining.

- Comprehensive Testing Regime

We customize our inspection plan based on customer requirements, ranging from standard chemical checks to advanced NDT.

- Chemical Analysis: Optical Emission Spectrometry (OES) to verify the precise range of Carbon (0.14-0.19%), Manganese, and Chrome.

- Mechanical Testing: Tensile strength, Yield strength, Elongation, and Hardness (HRc/BHN) verification.

- Non-Destructive Testing (NDT): To ensure internal soundness, we perform Ultrasonic Testing (UT) as per ASTM A388.

- Surface Inspection: Magnetic Particle Inspection (MPI) and Visual checks to detect surface cracks, seams, or laps.

- Metallography: Micro-structure analysis to confirm Grain Size (ASTM 5-8) and inclusion levels.

- Certification & Third-Party Inspection (TPI)

Traceability is non-negotiable.

- Mill Test Certificate (MTC): Every consignment is accompanied by a Test Certificate as per EN 10204 3.1, detailing the Heat Number, Chemical Composition, and Physical Properties.

- Secure Packaging & Logistics

To prevent transit damage and corrosion, particularly for our export and bright bar clients, we adhere to strict packaging standards.

- Bundling: Bars are securely strapped in 1MT to 2MT bundles using heavy-duty steel straps.

- Identification: Weather-proof metal tags are attached to each bundle, displaying: Grade (16MnCr5), Heat No, Size, and Colour Code.

Typical Applications of 16MnCr5 Steel

Due to its exceptional combination of surface hardness (60-62 HRC) and core toughness, 16MnCr5 (1.7131) is the preferred engineering steel for parts subject to high wear and fatigue stress.

- Transmission Gears: High-speed gears requiring fatigue resistance.

- Crown Wheels & Pinions: For differential gearboxes.

- Camshafts: Surface wear resistance is critical.

- Gudgeon Pins: Piston pins dealing with high shock loads.

- Crane Wheels: Capable of handling heavy rolling loads.

- Winch Axles: High core strength prevents snapping.

- Heavy Duty Bushes: Wear-resistant liners.

- Spindles: For machine tools and lathe centers.

- Collets & Tool Holders: Requires dimensional stability.

- Guide Pillars: For mold bases and die sets.

- Hydraulic Shafts: Often used in bright bar form.

- Fasteners: High-strength bolts and studs.