ST52-3 STEEL

What is ST52-3 Steel ?

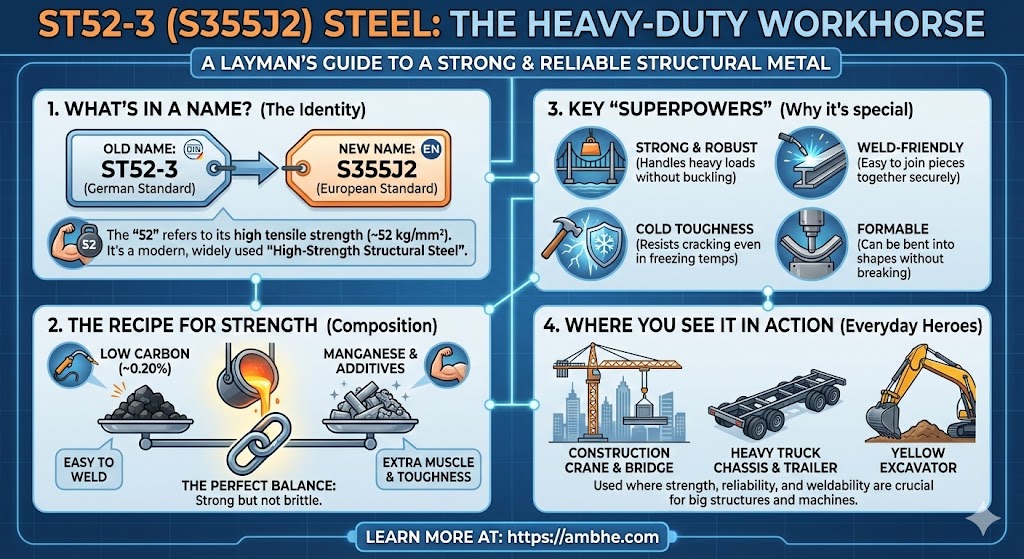

ST52-3 steel round bar is a type of low-alloy, high-strength steel that is also referred to as HSLA steel. St52 is a German grade (DIN 17100) equivalent to S355 in EN standards. The “St” stands for Stahl (German for steel), and “52” represents the minimum tensile strength of 52 kgf/mm² (~510 MPa).

It is widely used for manufacturing various industrial as well as domestic products and applications. It is equivalent to Indian IS2062 E350 grades of steel and EN S355JR and JIS SM490A. The ST52-3 round bar is known best and appreciated for its application-specific design, durability, dimensional accuracy, workability, weldability, excellent corrosion resistance, and long service life. These round bars are used in heavy-duty industries for several purposes.

The material is known for its excellent strength, toughness, and ductility, making it suitable for use in various applications. The chemical composition of ST52-3 steel includes elements such as carbon, manganese, silicon, phosphorus and sulphur.

One of the key properties of ST 52-3 steel is its high yield strength, which allows the material to withstand high-stress levels without undergoing significant deformation. The material also has good impact resistance, making it suitable for use in applications that involve dynamic loading or impact. Additionally, ST 52-3 steel has good weldability, making it easy to join using various welding techniques.

Further information on ST52 steel

ST 52-3 steel is commonly used in the construction industry to manufacture various structural components such as beams, columns, and plates. The material is also used to manufacture mechanical components such as shafts, gears, and gears. Additionally, it is used in the automotive industry to manufacture various components such as frames, suspension systems, and drive shafts.

The manufacturing of ST 52-3 steel typically involves a process of casting, followed by hot rolling, annealing, and normalizing, depending on end use. The material is then cooled and tempered to achieve the desired mechanical properties. The steel is then inspected and tested to meet the required specifications.

ST 52-3 steel is available in various forms, including plates, sheets, bars, and tubes. The material can be further processed through machining, cutting, and welding to create the desired product.

One of the advantages of ST 52-3 steel is its high strength-to-weight ratio, which makes it an ideal material for use in applications where weight is a critical factor. The material has good formability, making it easy to fabricate into complex shapes. It also has good machinability, allowing for easy and efficient machining operations.

ST 52-3 steel also has good corrosion resistance properties, making it suitable for various environments. However, it’s important to note that the corrosion resistance properties of the steel can be improved by applying a coat of paint or other protective coatings.

What are Limitations of ST52-3 Steel ?

There are some limitations to using ST 52-3 steel. The material is not suitable for use in applications that involve high-stress levels, as it may exhibit brittle behaviour under such conditions. Additionally, the material is not ideal for use in extremely high-temperature environments, as its strength and ductility may be adversely affected at such temperatures.

Applications of ST52-3 Steel Bars

ST52-3 steel round bar is widely used in manufacture of cold-work dies, punches, cold cutting scissors, drill bushes, gauges, wire-drawing dies, coining dies, draw bench boards, drawing dies, thread rolling dies, etc.

Sizes we offer in ST52.3 steel bars are:

About our Company

Ambhe Ferro Metal Processors Private Limited is a well-known and reputed manufacturer of IS2062 steel round bar situated in the state of Maharashtra, India. The location of our factories is near the port of JNPT and the major consumption centres of Mumbai, Thane, Pune, Nasik, Ahmednagar and Aurangabad.

Ambhe is manufacturing a wide range of round bars and other products as per the demand of customers. We make these bars in varied shapes and sizes so that we can fulfil all the needs and desires of customers. We manufacture our products keeping in mind the quality parameters and requirement set by the industry. These round bars are known best for their excellent features and quality. We manufacture high-quality bars as per domestic as well as global specifications as per the requirement of the customer.

We make use of top-notch quality of raw material and systems as per the needs of the customer. Kindly explore this website to know more about us.

Testing and Packaging

Testing and packaging are considered one of the most critical steps of the manufacturing process.

We do several tests and inspections to check the quality of ST52.3 steel round bar. Tests done depend on the requirement of the users. Those quality tests can include chemical composition test, physical test, visual inspection, macro and micro test, NDT test and ultrasonic test depending on the requirement of the customers. We can also arrange third-party inspection if required. A test certificate is given for each consignment for the tests conducted.

At last, we bundle or pack the ST52 round bar to prevent damage at the time of transportation.

Ordering Information

To order, the following information will be required

| Grade | ST52 |

| Order | Minimum order 3MT per size |

| Length | a) 5 To 6 Meters b) Custom Cut Length or multiple |

| Round Diameter | Rounds- 23.5mm, 24mm, 25mm, 26mm, 27mm, 28mm, 30mm, 32mm, 34mm, 36mm, 38mm, 40mm, 41mm, 42mm, 45mm, 46.5mm, 48mm, 50mm, 52mm, 53mm, 56mm, 58mm, 60mm, 63mm, 64mm, 65mm, 70mm, 73mm, 75mm, 80mm |

| Condition | Hot Rolled |

To request a quote kindly fill up this form.

Further Information

Chemical Properties of ST52-3 Steel Bars

| C | Si | Mn | P | S | N | Cu | CEV |

| max 0.22 | max 0.55 | max 1.6 | max 0.04 | max 0.04 | max 0.012 | max 0.55 | max 0.47 |

Markets we cater to

We supply St52.3 steel round bars to various national and international markets.

In India, we supply ST52 steel to a number of companies/industries in Mumbai (eg Vasai Virar, Mira Bhayendar, Navi Mumbai), Pune (eg. Pimpri Chinchwad, Chakan, Bhosari, Ranjangaon, etc), Aurangabad (eg. Waluj, Chikalthana, etc.), Nashik (eg. Ambad, Satpur, Sinnar, etc.), Ahmednagar, Rajkot, Ahmedabad, Thane, Umergaon, Ambernath, Rabale, Nagpur, Kolhapur, Sangli, Belgaum, Bangalore, Goa, Chennai, Dubai, RAK, etc.

Application of ST52 material

1. Construction Industry

- Applications: Beams, columns, structural components.

- Reasons: ST52 steel is chosen for its high yield and tensile strength, enabling it to handle heavy loads without deformation. Its weldability is a significant advantage in construction, allowing for easy assembly of structural components.

2. Shipbuilding

- Applications: Hulls, decks, superstructures.

- Reasons: ST52-3N, with its normalized properties, offers enhanced weldability and corrosion resistance, crucial for marine environments exposed to seawater.

3. Automotive Industry

- Applications: Chassis, axles, vehicle components.

- Reasons: The high strength and durability of ST52 ensure safety and performance in vehicles. Its formability allows for shaping into various components without compromising integrity.

4. Machinery Manufacturing

- Applications: Gears, shafts, equipment parts.

- Reasons: The mechanical properties of ST52, such as high tensile and yield strength, make it ideal for parts subjected to heavy loads and stresses.

5. Railway Construction

- Applications: Tracks, train components.

- Reasons: ST52’s strength and durability are beneficial for railway applications, where reliability and safety are paramount.

6. Oil and Gas Industry

- Applications: Pipelines.

- Reasons: ST52’s strength and weldability make it suitable for pipelines, though additional coatings may be needed for extreme corrosion environments.

Why ST52 Steel is Preferred

- Cost-Effectiveness: ST52 offers a balance of affordability and performance, being more economical than high-alloy steels.

- Availability: Widely produced and easily sourced, making it a convenient choice.

- Durability: Its chemical composition, including manganese and silicon, enhances strength and resistance to wear.

- Weldability: Essential for construction and manufacturing, facilitating easy and strong joints.

Considerations and Limitations

- High-Temperature Applications: ST52 may not be the best choice for extreme heat, requiring alternative materials.

- Corrosion Resistance: While durable, harsh environments may necessitate additional protective coatings.