EN1A STEEL

EN1A FREE CUTTING STEEL

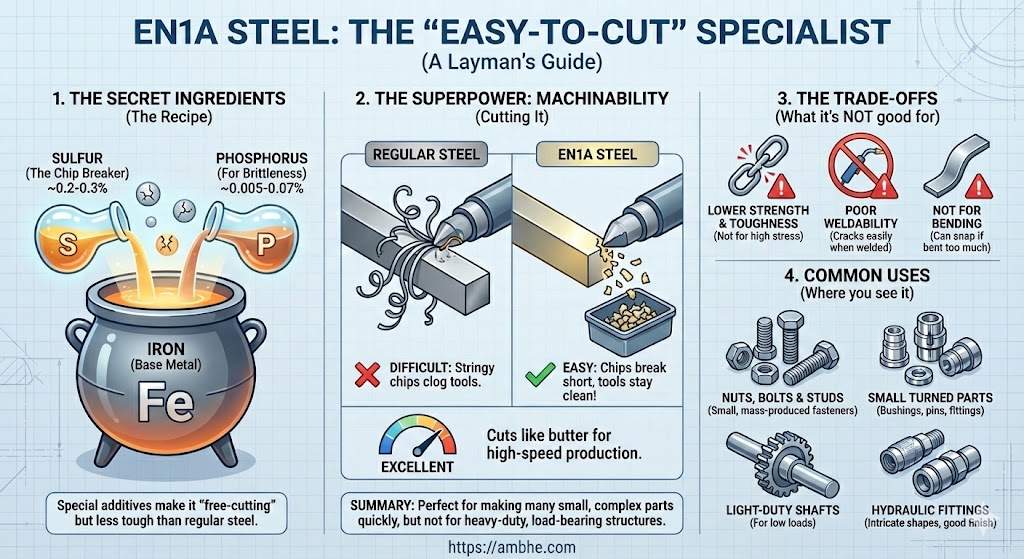

EN1A is a very popular grade of low carbon-manganese free cutting steel, which is most suitable for the manufacture of repetition turned components, such as nuts, bolts, hydraulic fittings and studs, particularly where intricate drilling and machining operations are involved. If you want a quote kindly email us at sales@ambhe.com.

It can be case-hardened, producing components with enhanced wear resistance. En1a is also available as En1a leaded (En1aPb) for greater machinability. Swarf will form in small chips to prevent machine blockage.

EN1aNL steel is a non-leaded Re-Sulphurised Free Machining Steel. This is a premium grade of free cutting steel. It has excellent machinability. It is suitable for case hardening and electroplating. We can provide you with free cutting steel both in the black and bright cold drawn bar form.

Applications of En1a Steel

En1a steels are suitable for applications where good machinability is the prime consideration. Because of this, they are used for the rapid production on single or multiple spindle automatic lathes and capstan lathes of finely finished components which will not be subjected to high stresses in service, e.g. light duty studs, cycle components and many intricate parts for textile and printing machinery.

This type of steel cannot be relied upon to possess good transverse properties and should not be used for hollow parts which might be subjected to an internal pressure which would set up wall stresses dangerously near to the transverse yield stress.

Case hardening can be carried out but this steel Is not recommended for general case hardening work and it is not intended for use where the hardened case is subject to severe impact in service.

Typical applications are Brake hose end, hydraulic parts, pulleys, disc brake pistons, wheel nuts and inserts, control linkages, hear box components (case hardened), domestic garbage bin axles, concrete anchors, padlock shackles, hydraulic fittings, vice jaws. En1a steel bars are used mostly in the bright form.

Location and Markets

- Round Black from sizes 23.5mm to 80mm

- Bright Bar from sizes 22mm to 63.5mm

- Hexagons Black from 23.5mm to 52.5mm

- Hexagon Bright bar from 22mm to 50mm

Chemical Composition of En1a Steel Rounds

| Element | Min | Max |

|

Carbon, C |

0.07 |

0.15% |

| Manganese, Mn | 0.80 | 1.20% |

|

Silicon, Si |

0.00 |

0.10% |

|

Sulfur, S |

0.2 |

0.3 |

|

Phosphorous, P |

0.00 |

0.07 |

Mechanical Properties of En1a Steel Rounds

| Max Stress | 370-480 n/mm2 Min | dependent on ruling section |

|

Yield Stress |

240-400 n/mm2 Min |

dependent on ruling section |

| 0.2% Proof Stress | 225-360 n/mm2 Min | dependent on ruling section |

|

Elongation |

6-10% Min |

dependent on ruling section |

World-wide Grades similar to En1a Steel

| BS970: 1955 | EN1A |

| BS970/PD970: 1970 onwards | 230M07 |

| European | 9SMn28, BS En 11SMn30 |

| Werkstoff No. | 1.0715 |

|

US SAE (AISI) |

1213, 1215 |

Heat Treatment of En1a Steel

- Carbonisation of EN1A bright mild steel takes place at 900-950oC then it is furnace or air cooled.

- En1A can be tempered at 180-210 oC then should be left to cool in air.

- The mild steel can be hardened at 780-800oC then quenched in oil or water. However this is difficult to do with EN1A and is not recommended.

About Ambhe Ferro

Ambhe Ferro Metal Processors Private Limited is a well-known and reputable manufacturer of En1a free-cutting round steel bars in the state of Maharashtra, India. Our factories are located near the port of JNPT and the major consumption centres of Mumbai, Thane, Pune, Nasik, Ahmednagar, and Aurangabad.

Ambhe manufactures a wide range of round bars and other products as per customer demand. We make bars in different shapes and sizes to meet all customer needs. We manufacture our products keeping in mind the quality parameters and requirements set by the industry. These round bars are known best for their excellent features and quality. We manufacture high-quality bars as per domestic as well as global specifications as per the requirements of the customer.

We make use of top-notch quality of raw material and systems as per the needs of the customer. Please explore this website to learn more about us.

Testing and Packaging of En1a Steel

Testing and packaging are considered one of the most critical steps of the manufacturing process.

We do several tests and inspections to check the quality of En1a steel round bar. Tests done depend on the requirement of the users. Those quality tests can include chemical composition test, physical test, visual inspection, macro and micro test, NDT test and ultrasonic test depending on the requirement of the customers. We can also arrange third-party inspection if required. A test certificate is given for each consignment for the tests conducted.

At last, we bundle or pack the En1a round bar to prevent damage at the time of transportation.

Ordering Information of En1a Round Bar

To order, the following information will be required

| Grade | En1a |

| Order | Minimum order 5MT per size |

| Length | a) 5 To 6 Meters b) Custom Cut Length or multiple |

| Round Diameter | 23.5 mm to 80 mm |

| Hexagon | 23.5mm to 52.5mm |

| Condition | a) Hot Rolled b) Bright Bar |

To request a quote kindly fill up this form.

Properties of En1a Steel

- High Strength: EN1A steel is a low carbon, free-cutting steel that has high strength and hardness properties.

- Good Machinability: The steel has excellent machinability characteristics, making it easy to work with using conventional machine tools.

- Good Surface Finish: The steel has a smooth surface finish, making it ideal for parts that require a high level of surface finish.

- High Wear Resistance: The steel has high wear resistance, making it ideal for parts that are subjected to high levels of wear and tear.

- Low Carbon Content: The steel has a low carbon content, making it suitable for applications that require low carbon steels.

- Good Corrosion Resistance: The steel has good corrosion resistance, making it suitable for parts that are exposed to the elements.

- Low Hardness: The steel has a low hardness, making it easy to work with and machine.

- Good Ductility: The steel has good ductility, making it easy to form and bend.

- Good Weldability: The steel has good weldability, making it easy to join and fabricate.

- Low Cost: The steel is relatively inexpensive, making it an affordable option for many applications.

Markets for our En1a Round Bar

We supply En1a to various national and international markets.

In India, we supply En1a steel to a number of companies/industries in Mumbai (eg Vasai Virar, Mira Bhayendar, Navi Mumbai), Pune (eg. Pimpri Chinchwad, Chakan, Bhosari, Ranjangaon, Katraj, etc), Aurangabad (eg. Waluj, Chikalthana, etc.), Nashik (eg. Ambad, Satpur, Sinnar, etc.), Ahmednagar, Rajkot, Ahmedabad, Thane, Umergaon, Ambernath, Rabale, Nagpur, Kolhapur, Sangli, Belgaum, Bangalore, Goa, Chennai, UAE, etc.

EN 1A is low carbon material. Available in round, hexagon or square form.