IS2062 STEEL

IS 2062 Steel Round Bars: The Backbone of Structural Engineering (Grades E250 & E350)

What are IS 2062 Steel Round Bars?

IS 2062 Round Bars are solid, cylindrical steel bars manufactured under the Bureau of Indian Standards (BIS) specification for Hot Rolled Medium and High Tensile Structural Steel. Widely regarded as the standard for general engineering and construction in India, these bars are prized for their excellent weldability, ductility, and superior structural integrity.

Often referred to as Mild Steel (MS) Rounds or structural rounds, they form the fundamental support components in industries ranging from infrastructure development and power plants to automotive engineering.

Understanding the Standard: IS 2062

The IS 2062 standard governs the chemical and mechanical properties of steel used for structural purposes. Unlike generic steel, IS 2062 certified material guarantees a specific Minimum Yield Strength (MYS) and tensile strength, ensuring safety and reliability in critical load-bearing applications.

While the standard covers various profiles (beams, channels, angles), the round bar profile is unique for its versatility in machining, threading, and forging.

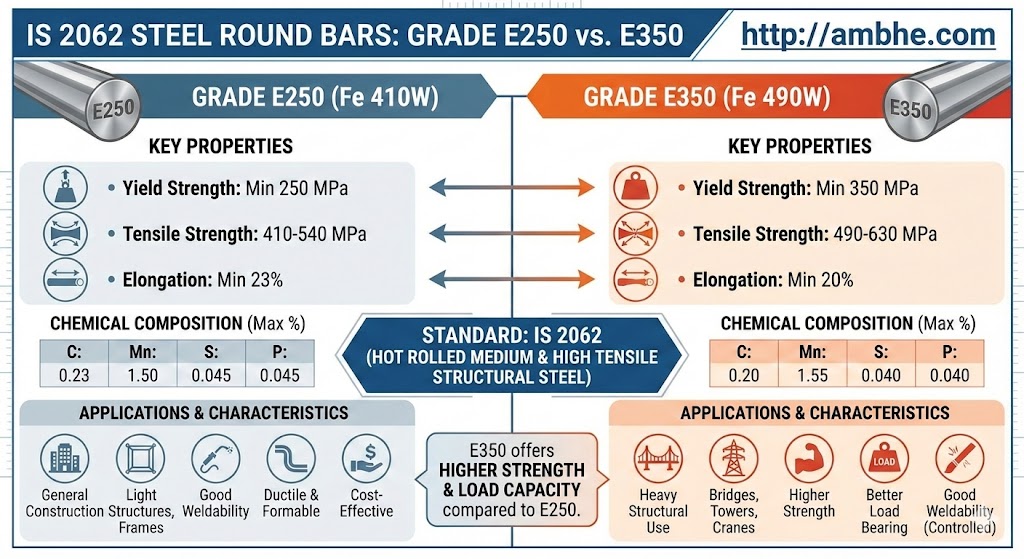

Grade E250: The Industry Standard (Fe 410W)

Grade E250 is the most widely consumed structural steel grade in India. Historically known as Grade A or Fe 410W, it serves as the baseline for general-purpose construction.

Yield Strength: Minimum 250 MPa.

Tensile Strength: 410 MPa.

Key Characteristics:

High Ductility: Can be bent and formed without cracking.

Excellent Weldability: Low carbon content (approx. 0.23% max) allows for easy welding without pre-heating.

Cost-Effective: Offers the best balance of strength-to-cost for non-critical structures.

Typical Applications: E250 round bars are used in general fabrication, window grills, gates, automotive chassis components, and foundation bolts where extreme loads are not expected.

Grade E350: High Tensile Structural Steel (Fe 490W)

Grade E350 is a high-strength variant designed for heavy-duty applications. Known as Fe 490W, this grade is engineered to support heavier loads with a lighter material footprint.

Yield Strength: Minimum 350 MPa.

Tensile Strength: 490 MPa.

Key Characteristics:

Superior Load Bearing: Supports significantly higher loads than E250, allowing engineers to use thinner diameters to achieve the same strength.

Micro-Alloyed: Often includes micro-alloying elements like Niobium or Vanadium to boost strength without sacrificing weldability.

Impact Resistance: Better suited for dynamic loading conditions (vibrations, moving loads).

Typical Applications: E350 round bars are essential in high-rise construction, heavy machinery shafts, crane booms, transmission towers, and offshore structures.

About our Company

Ambhe Ferro Metal Processors Private Limited is a well-known and reputed manufacturer of IS2062 steel round bar situated in the state of Maharashtra, India. The location of our factories is near the port of JNPT and the major consumption centres of Mumbai, Thane, Pune, Nasik, Ahmednagar and Aurangabad.

Ambhe is manufacturing a wide range of round bars and other products as per the demand of customers. We make these bars in varied shapes and sizes so that we can fulfil all the needs and desires of customers. We manufacture our products keeping in mind the quality parameters and requirement set by the industry. These round bars are known best for their excellent features and quality. We manufacture high-quality bars as per domestic as well as global specifications as per the requirement of the customer.

We make use of top-notch quality of raw material and systems as per the needs of the customer. Kindly explore this website to know more about us.

Testing and Packaging

Testing and packaging are considered one of the most critical steps of the manufacturing process.

We do several tests and inspections to check the quality of IS2062 steel round bar. Tests done depend on the requirement of the standard and the users. Those quality tests can include chemical composition test, physical test, visual inspection, macro and micro test, NDT test and ultrasonic test depending on the requirement of the customers. We can also arrange third-party inspection if required. A test certificate is given for each consignment for the tests conducted.

At last, we bundle or pack the IS2062 round bar to prevent damage at the time of transportation.

Contact us for IS2062 Steel

Would you like to know the pricing for IS2062 bars?

Contact us

Via email: sales@ambhe.com

Via Telephone: +91 9004064570

For more detailed contact information visit Contact Us.

Chemical composition % of the Product analysis of grade IS 2062 E250 (Fe 410WA) steel

| C | Si | Mn | N | P | S | CEmax | Cu |

| max 0.23 | 0.40 max | 1.50max | max 0.012 | max 0.045 | max 0.045 | 0.42 |

Ordering Information

| Grade | IS2062 Grade E250A, E275A, E300A, E350A |

| Order | Minimum order 3MT per size |

| Length | 3 To 6 Meters, Custom Cut Length or multiple |

| Diameter | 23.5 mm to 80 mm |

| Condition | a) Hot Rolled b) Bright Bar |

To request a quote kindly fill up this form.

Further Information on IS2062 Steel

Markets