42CrMo4 STEEL

42CrMo4 STEEL GRADE

42CrMo4 is an engineering alloy steel containing chromium and molybdenum. It has high fatigue strength, abrasion and impact resistance, toughness, and torsional strength. It can be heat treated in a number of ways to give it a superior combination of properties. It is equivalent to SAE 4140 and En19 steel grades with minor differences in chemical ranges.

We can provide you 42CrMo4 in the following forms

- Rounds (As rolled) – 23.5mm to 80mm

- Hexagons (As rolled) – 23.5mm to 52.5mm

- Round Cornered Square (RCS) – 55mm to 75mm

- Bright Bars (Rounds)- 22mm to 63.5mm

About our Company

Your Strategic Partner for Engineering Steel in Western India.

Ambhe Ferro Metal Processors Pvt. Ltd. stands as a trusted name in the steel processing industry. We combine technical expertise with an unbeatable location advantage.

Strategic Logistics: Located near the JNPT Port, we offer efficient export solutions and just-in-time delivery to the Maharashtra industrial belt (Mumbai-Pune-Nashik-Aurangabad).

Customized Manufacturing: From commercial grades to specialized alloy steels, we manufacture round bars that fit your exact chemical and mechanical requirements.

Uncompromised Quality: By sourcing top-tier raw materials and adhering to strict quality control protocols, we deliver steel that drives performance and reliability for our clients.

Supply Specifications & Ordering Information for 42CrMo4 steel

To order, the following information will be required by us

| Grade | 42CrMo4 |

| Order | Minimum order 5MT per size |

| Length | a) 5.5 To 6 Meters b) Custom Cut Length or multiple |

| Round Diameter | 23.5 mm to 80 mm (in straight lengths) |

| Condition | a) Hot Rolled b) Bright Bar e) QT – Peeled – Ground |

To request a quote kindly fill up this form.

We are supplier of 42CrMo4 bars to a number of companies in Mumbai, Pune (eg Chakan, Bhosari, Ranjangaon, etc), Aurangabad, Nashik, Ahmednagar, Rajkot, Thane, Nagpur, Belgaum, Kolhapur, Sangli, Chennai, Bangalore, etc. All our 42CrMo4 supplied is Ultrasound and MPI inspected.

Ordering Contact Information for 42CrMo4 steel bars

Want to Order?

Get competitive pricing and immediate delivery for 42CrMo4 Steel. Contact our Mumbai sales office today.

(Response within 24 Hours)

🌍 International Equivalents to 42CrMo4 Steel

The most common international equivalents for 42CrMo4 (DIN 1.7225) are:

- 🇺🇸 USA: AISI 4140 / SAE 4140

- 🇬🇧 UK: En19 / 709M40

- 🇯🇵 Japan: JIS SCM440

📋 Comprehensive Cross-Reference Table

| Region / Country | Standard | Grade / Designation |

|---|---|---|

| 🇪🇺 Europe (EU) | EN 10083-3 | 1.7225 / 42CrMo4 |

| 🇩🇪 Germany | DIN 17200 | 1.7225 / 42CrMo4 |

| 🇺🇸 USA | AISI / SAE / ASTM | 4140 / 4142 |

| 🇬🇧 United Kingdom | BS 970 | En19 / 708M40 / 709M40 |

| 🇯🇵 Japan | JIS G4053 | SCM 440 |

| 🇫🇷 France | AFNOR | 42 CD 4 / 42 CD 4 u |

| 🇮🇹 Italy | UNI | 42 CrMo 4 |

| 🇨🇳 China | GB/T 3077 | 42CrMo |

| 🇸🇪 Sweden | SS | 2244 |

| 🌐 International | ISO 683-1 | 42CrMo4 |

While AISI 4140 and 42CrMo4 are often sold as "Dual Certified," they have slight variations.

- Manganese: AISI 4140 allows 0.75-1.00%, while 42CrMo4 allows 0.60-0.90%.

- Sulphur/Phosphorus: European standards (EN) often require tighter controls on S and P (max 0.035%) compared to standard commercial quality 4140.

📚 Frequently Asked Questions: 42CrMo4 Steel Guide

What is 42CrMo4 steel?

What does the name "42CrMo4" mean?

- 42: Indicates an average Carbon content of 0.42%.

- Cr: Indicates Chromium is the primary alloying element.

- Mo: Indicates Molybdenum is present.

- 4: Indicates the Chromium content is approx. 4 / 4 = 1%.

Is 42CrMo4 the same as AISI 4140?

What is the Werkstoff Number for 42CrMo4?

What is the density of 42CrMo4?

What is the hardness of 42CrMo4 in Q+T condition?

What is the maximum hardness achievable?

Is 42CrMo4 magnetic?

Is 42CrMo4 weldable?

What is the machinability of 42CrMo4?

What is the tempering temperature for 42CrMo4?

- 540°C: Higher Strength, Lower Toughness.

- 650°C: Higher Toughness, Lower Strength (Preferred for shafts).

Can 42CrMo4 be Nitrided?

What is the difference between 42CrMo4 and En19?

Is 42CrMo4 corrosion resistant?

Does 42CrMo4 have good impact resistance?

What is the difference between 42CrMo4 and C45?

- C45: Only hardens on the surface; the core remains soft in large sections. Lower strength.

- 42CrMo4: Has "Deep Hardenability." It can be hardened to the core even in thick bars (up to 100mm+), offering vastly superior strength and fatigue life.

Chemical Composition of 42CrMo4 Steel Bars

Chemical Composition: 42CrMo4 vs 42CrMoS4

Chemical Composition: 42CrMo4 vs 42CrMoS4

What is the difference between 42CrMo4 and 42CrMoS4?

What is the difference between 42CrMo4 and 42CrMoS4?The primary difference is the Sulphur (S) content.

• 42CrMo4 (1.7225) has low sulphur (Max 0.035%) for high fatigue strength and purity.

• 42CrMoS4 (1.7227) has controlled higher sulphur (0.020% – 0.040%) to promote Machinability. The added sulfur forms manganese sulphide inclusions which act as chip breakers during automated machining.

| Element | Symbol | 42CrMo4 (1.7225) % | 42CrMoS4 (1.7227) % |

|---|---|---|---|

| Carbon | C | 0.38 – 0.45 | 0.38 – 0.45 |

| Silicon | Si | Max 0.40 | Max 0.40 |

| Manganese | Mn | 0.60 – 0.90 | 0.60 – 0.90 |

Sulfur  | S | Max 0.035 | 0.020 – 0.040 |

| Phosphorus | P | Max 0.025 | Max 0.025 |

| Chromium | Cr | 0.80 – 1.20 | 0.90 – 1.20 |

| Molybdenum | Mo | 0.15 – 0.30 | 0.15 – 0.30 |

Standard Reference: EN 10083-3:2006

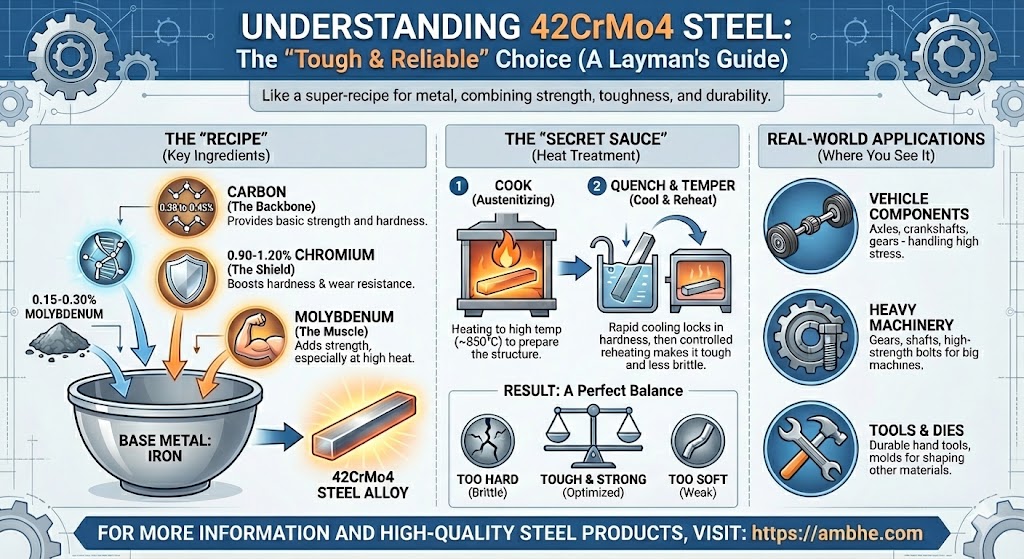

Role of Alloying Elements

Role of Alloying Elements

Why are these specific elements added? Here is the breakdown of how chemistry affects performance:

C Carbon (0.41%)

Provides the base hardness and tensile strength. Allows the steel to be heat treated to 55+ HRC via induction.

Cr Chromium (1.1%)

Crucial for Hardenability. It allows the steel to harden deeper into the core during quenching, not just the surface.

Mo Molybdenum (0.2%)

Prevents temper brittleness and improves high-temperature strength. It ensures the steel stays tough after tempering.

S Sulphur (Variable)

In 42CrMoS4: Improves machinability by creating chip-breaking inclusions.

In 42CrMo4: Kept low to maximize transverse impact strength.

MATERIAL PROPERTIES OF 42CrMo4 FOR FABRICATION AND HEAT TREATMENT

Comprehensive guide to processing DIN 1.7225 (AISI 4140) Steel: Forging, Welding, Machining, and Hardening.

42CrMo4 is a heat-treatable steel with excellent machinability in the Annealed condition (approx. 217 HB). However, it has poor weldability due to its high carbon content (0.42%) and requires preheating to 200°C–300°C to prevent cracking. The optimal heat treatment involves hardening at 850°C followed by oil quenching and tempering between 540°C–680°C to achieve high tensile strength (900–1200 MPa).

🔥 Heat Treatment Process Parameters

Achieving the correct mechanical properties relies on precise temperature control. Use the table below for setting furnace parameters.

| Process Step | Temperature Range (°C) | Cooling Medium | Purpose |

|---|---|---|---|

| Forging | 850°C – 1050°C | Air / Sand (Slow) | Hot forming of components. |

| Soft Annealing | 680°C – 720°C | Furnace Cool | Improves machinability (Max 241 HB). |

| Normalizing | 840°C – 880°C | Still Air | Refines grain structure before hardening. |

| Hardening | 820°C – 860°C | Oil (Preferred) or Water | Transformation to Martensite structure. |

| Tempering | 540°C – 680°C | Air | Restores toughness and ductility. |

📈 Iron-Carbon Phase Diagram

Understanding the austenitizing zone is critical. 42CrMo4 must be heated above the AC3 line (approx 820°C) to fully dissolve carbides.

⏱️ TTT Diagram (Time-Temp-Transformation)

The diagram dictates your cooling speed. You must quench fast enough (usually in oil) to miss the “nose” of the curve and avoid forming Pearlite.

🛠️ Fabrication Characteristics

🗜️ Machinability

- Best Condition: Soft Annealed (~200 HB).

- Difficulty: Medium. It machines well but requires robust tooling due to its toughness.

- In Q+T Condition: Machining is possible up to 30-32 HRC (Pre-hardened), but tool wear increases significantly.

- Surface Finish: Excellent, especially after grinding.

⚡ Weldability

- Rating: Poor / Difficult.

- Risk: High risk of Cold Cracking (Hydrogen Induced Cracking) in the Heat Affected Zone (HAZ).

- Requirement: Parts MUST be preheated to 200°C–300°C.

- Post-Weld: Stress relieving at 550°C–600°C is highly recommended immediately after welding.

- Filler Material: Low hydrogen electrodes (e.g., E8018-B2).

💪 Mechanical Properties (Quenched & Tempered)

Properties vary by diameter due to the “Ruling Section” effect. Smaller diameters achieve higher core strength.

| Diameter (mm) | Yield Strength (Re) | Tensile Strength (Rm) | Elongation (A5) | Impact Energy (KV) |

|---|---|---|---|---|

| Up to 16mm | > 900 MPa | 1100 – 1300 MPa | > 10% | – |

| 16mm – 40mm | > 750 MPa | 1000 – 1200 MPa | > 11% | > 35 J |

| 40mm – 100mm | > 650 MPa | 900 – 1100 MPa | > 12% | > 35 J |

| 100mm – 160mm | > 550 MPa | 800 – 950 MPa | > 13% | > 35 J |

Disclaimer: Data is for reference only and based on EN 10083-3 standards. Always verify with specific Mill Test Certificates.

Quality Assurance, Testing & Packaging for 42CrMo4

Ensuring Integrity from Mill to Manufacturing

All 42CrMo4 (DIN 1.7225) steel supplied undergoes rigorous Quality Assurance (QA) to meet ISO 9001 standards. Critical applications require 100% Ultrasonic Testing (UT) according to ASTM A388 to ensure internal soundness, alongside strict chemical verification and mechanical testing. Material is supplied with a Mill Test Certificate (EN 10204 3.1) to guarantee traceability.

🔬 Rigorous Testing Protocols

To ensure the material is free from internal defects and meets the required mechanical properties, the following tests are mandatory:

| Non-Destructive Testing (NDT) 📡 | Lab & Mechanical Testing 🧪 |

|---|---|

Why: To detect internal cracks, voids, or inclusions that could cause failure.

|

Why: To verify the steel grade and strength.

|

📦 Packaging & Identification Standards

Proper packaging prevents transit damage and ensures easy identification at the customer's site.

- 🎨 Colour Coding: Ends are painted with a specific color code to distinguish 42CrMo4 from other grades like En24 or 4140 instantly.

- 🏷️ Tagging: A weather-proof metal or PVC tag is attached displaying: Grade, Size, Heat Number, and Supplier Name.

📄 Documentation (The MTC)

Every dispatch is accompanied by a Mill Test Certificate (MTC) in accordance with EN 10204 Type 3.1. This includes actual chemical analysis results, mechanical test values, and confirmation of heat treatment condition.

Applications of 42CrMo4 Steel: Industry & Engineering Uses

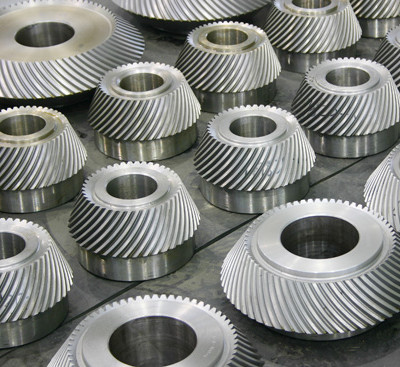

Our 42CrMo4 steel is used in various application such as

- Fasteners

2. Shafts

3. Crankshaft

4. Machinery Parts

5. Gears

6. Steel Collets

7. Conveyors and Rolls

8. Steel Couplings

9. Drill Collars

10. Steel Piston Rods

11. Steel Ejector

12. And many more…

Detailed Breakdown by Industry

Automotive Components: In the automotive sector, 42CrMo4 is the material of choice for power transmission parts. It is widely used for crankshafts in heavy trucks and performance vehicles because it resists bending and torsional stress. It is also essential for steering knuckles and axle shafts, where safety and resistance to sudden impact loads are critical.

Heavy Engineering & Machinery: For industrial equipment, this grade is used to manufacture conveyor rollers, logging tools, and pinion gears. Its ability to be induction hardened (achieving surface hardness of 55+ HRC) while maintaining a tough core makes it ideal for parts that face high surface wear but must not snap under load.

Oil & Gas Exploration: The material is extensively used for drill collars and high-pressure valves. Deep-hole drilling operations require materials that maintain mechanical integrity under high pressure and corrosive conditions; 42CrMo4 provides the necessary depth of hardenability to ensure the component is strong throughout its entire cross-section, not just the surface.

Fasteners & Fixings: It is a primary raw material for manufacturing high-tensile studs and anchor bolts used in wind turbines and structural engineering, particularly where temperatures may fluctuate, as 42CrMo4 offers good temper stability.